Frequently asked questions (FAQ)

+ -

What is an automatic weighing and bagging machine?

What is an automatic weighing and bagging machine?

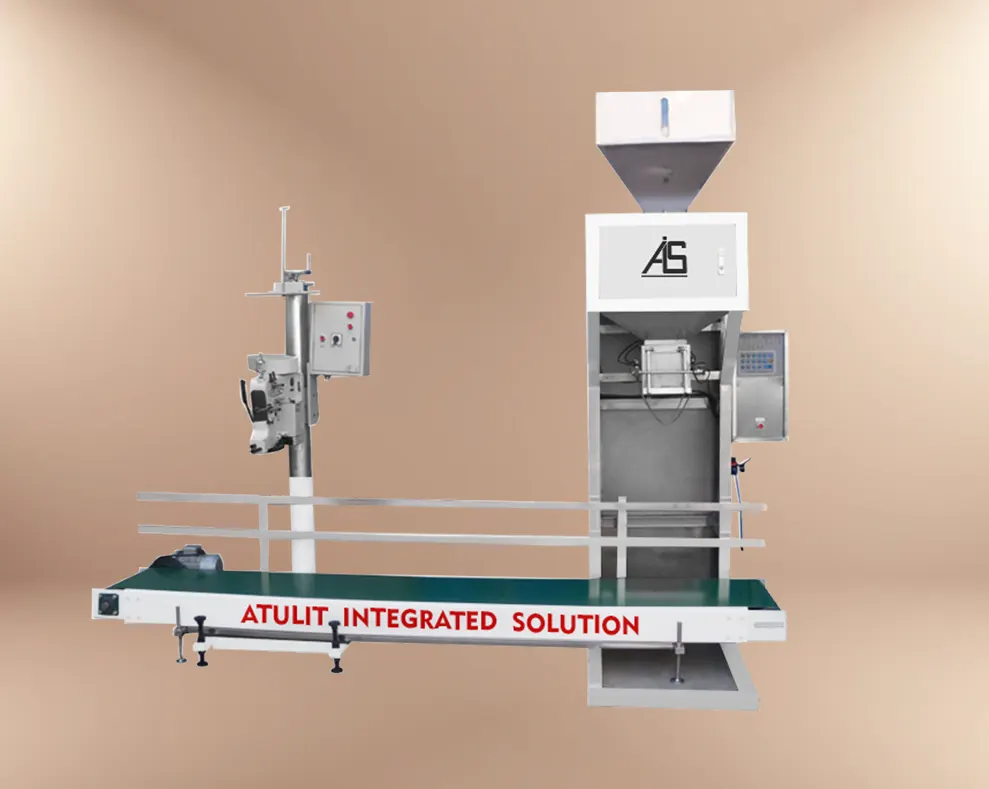

Atulit Integrated Solutions automatic weighing and bagging machine is a specialized

industrial equipment used to accurately weigh and package various products into bags or containers

automatically. It is commonly used in industries such as agriculture, food processing, pharmaceuticals and

more.

+ -

How does AIS Automatic Weighing and Bagging Machine work?

How does AIS Automatic Weighing and Bagging Machine work?

Atulit Integrated Solutions machine work by first measuring the weight of the

product using load cells weight measurement technology. Once the desired weight is achieved, the machine

dispenses the product into a bag or container and then seals it as well. The entire process is automated and

can be customized based on the product and packaging requirements.

+ -

What types of products can be weighed and bagged using AIS machines?

What types of products can be weighed and bagged using AIS machines?

Automatic weighing and bagging machines can handle a wide range of products,

including granular materials like grains, seeds and fertilizers as well as powders, liquids and even non-food

items like hardware components and pharmaceuticals.

+ -

What are the advantages of using AIS Automatic Weighing And Bagging

Machines?

What are the advantages of using AIS Automatic Weighing And Bagging

Machines?

The advantages are:

• Increased efficiency and productivity.

• Improved accuracy in weighing and packaging.

• Reduces labour costs and gives more output.

• Consistency in product quality and packaging.

• Compliance with regulatory requirements.

• Reduced risk of contamination or human error.

+ -

How do we choose the right automatic weighing and bagging machine for

our business?

How do we choose the right automatic weighing and bagging machine for

our business?

Consider factors such as the type of product you are packaging, required throughput,

bag size and material, accuracy requirements and budget. Consulting with knowledgeable and experts of Atulit

Integrated Solutions technical support engineering team will be helpful in making the best choice for your

specific needs.

+ -

Are AIS machines easy to maintain?

Are AIS machines easy to maintain?

Maintenance requirements vary by machine type and manufacturer. Regular cleaning,

calibration and inspection are generally needed to ensure optimal performance. Some machines may require more

specialized maintenance, so it's essential to follow the AIS specified guidelines.

+ -

Can AIS Automatic Weighing and Bagging Machines be integrated into

existing production lines?

Can AIS Automatic Weighing and Bagging Machines be integrated into

existing production lines?

Certainly Yes, Atulit Integrated Solutions machines are designed to be integrated

seamlessly into existing production lines. It requires some customization and adjustments to ensure a smooth

workflow.

+ -

What is the lifespan of AIS automatic weighing and bagging machine?

What is the lifespan of AIS automatic weighing and bagging machine?

The lifespan can vary depending on usage, maintenance and the quality of the

machine. On average, a well-maintained and properly run machine can last more than 10 years or even longer.

+ -

Can these machines handle different bag sizes and packaging materials?

Can these machines handle different bag sizes and packaging materials?

AIS Automatic Weighing and Bagging Machines are adaptable and can handle various bag

sizes and materials. However, the specific capabilities depend on the machine's design and configuration. Be

sure to discuss your requirements with Atulit Integrated Solutions technical support engineering team. This

will be helpful in making you the best choice.

+ -

Are there any safety considerations when using these machines?

Are there any safety considerations when using these machines?

Yes, safety is crucial when operating these machines. Employees should be trained

for their proper use and safety features like emergency stops and guarding should be in place to prevent

accidents. Regular safety inspections are also essential.

Always consult the Atulit Integrated Solutions technical support engineering team and follow the guidelines

for your specific Automatic Weighing and Bagging Machine to ensure safe and efficient operation.